Components of BS Plastics

Burnt shale filler

+

Polymer

=

Plastic

BS Polymer components

- Circular Economy

- Saved CO2 emission

- Decreased mining minerals

- New burnt shale-based polymer composite contains 85% of burnt shale and only 15% traditional polymers.

- This innovative way to produce the plastics makes process to eco-friendly .

Read more

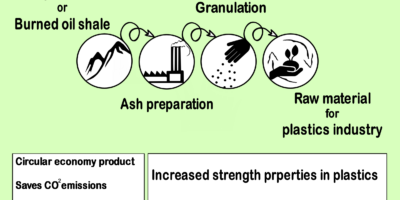

The oil shale industry in Estonia produces about 80% of the energy consumed in the country itself and exports energy to its neighbour countries. In addition to the oil shale, the energy production process also involves many by-products. The main product, which accounts for about 55% of all, is burnt oil shale, also known as oil shale ash. For oil shale ash to become a suitable material for the polymer industry, it needs to be technologically processed. We offer technology, which helps to create a unique product for the polymer industry – kukermite plastics. This also helps to prevent the creation of ash mountains.

During the production of energy, burnt oil shale will fill the electric filters. This material’s attributes are very similar to chalk that is used as filler in the polymer industry. Mineralplast OÜ has created a method which helps to do that in the most effective way – the outcome is a product with 85% of kukermite mixed with, for example, PP (polypropylene).

During the production of energy from oil shale, oil shale ash is created and right now it is stored as ash mountains in Estonia – it is not very nature-friendly solution. Also, the share of plastic is always growing in the world and it is not wise to produce all new materials for it but rather use by-products and give them new life. By using the oil shale ash, we would prevent the ash mountains as well as heavily reduce using new materials for plastics creation.

Processing the kukermite

- Kukermite is a solid substance, that remains in the burning of shale.

- Read the Kukermite technical data sheet

Improved

- The product is more stable when processing

- Material's temperature stability increases

- The product will gain additional stiffness

- Mixes well with plastics even in high concentrations

- Hardness 3 grade according to Mohs scale

- Laboratory report: Hardness and abrasiveness of oil shale ash

Can be used almost everywhere

Did you know

92% of the world’s oil shale production is consumed in Estonia.

Annually creates 6-7 million tons of burnt shale ash.

Let’s use it all!

Call for opportunities